Solar control glass

For many years architects and designers have been looking for new construction materials that would open up the commercial and residential buildings to the exterior world. They have been fascinated with the properties of glass which proved to be the perfect construction material for the modern era.

It offers quality and beauty, helps save energy, and allows for easy assembly. Among its various qualities, there is one which is especially useful for offices and public facilities, namely solar protection. Solar control glass adds character to a building and reduces undesirable heating of the elevation regarding a type of coating.

Types of solar control glass

Solar control glass can be divided into absorptive and reflective glass, based on their visual characteristics and the ability to reduce solar radiation. PRESS GLASS offers three types of solar control glass:

– THE SELECTIVE float glass – flat and transparent, neutral or dyed to blue, brown, grey or green in the glass structure, and coated with a metal oxide multilayer, with the aim of achieving the appropriate effect of reflection, control of isolation of rooms, as well as limiting the penetration of solar energy plus a high level of thermal protection. It may be used only in double glazing.

– THE ABSORPTIVE float glass, flat and transparent, with blue, brown, grey or green tint. It may be used in single glazing or double glazing. This is applied to reduce the transmittance of solar energy.

– THE REFLEXIVE float glass – flat and transparent, neutral or dyed to blue, brown, grey or green in the glass structure, while also coated with metal oxides for proper reflective effect. This is applied to control light, and reduce solar energy transmittance. It may be used in single glazing or double glazing – regarding a type of coating.

Optimal temperature in rooms

The level and distribution of air temperatures has a significant impact on our comfort while indoors. Until recently it was possible to feel a dramatic drop in temperature near a window during the winter, which could produce a strong feeling of discomfort. Thanks to the application of thermally insulated glass unit which amounts to 70% of the window surface it is possible to eliminate this problem the range of temperatures are not subjected to any heat discomfort.

A different problem can arise in the summer, when the sunrays overheat the inside of a building. This problem can be rectified by reflexive solar control and selective solar control glass which, thanks to its special construction, limits overheating while maintaining a high level of light transmission. A similar function is also provided by thermal control glass, but to a lesser degree; this is compensated by the benefit of higher heat retention performance during winter that thermal control glass offers.

Reducing the costs of ventilation

As in the winter period when there is a necessity to heat a building, likewise in the summer period there is heating of parts of the building on the southern, south-eastern and south-western parts. Sunshine which is evident during the day emits a lot of heat energy, which during winter is seen as additional heat which heats up a building, while in summer it causes excessive rises in temperature causing discomfort and worsening of work conditions. In order to reduce temperature in homes or office buildings air-conditioning systems are commonly used. This is associated with additional costs and it is worth noting that the costs of cooling buildings is higher than the costs of heating.

So as to reduce the costs of cooling it is necessary to apply the following types of glass in windows and facades of buildings:

– Solar control glass units which are dyed in mass

– Reflexive solar control glass units

Reducing the light transmission

The application of such glass, especially that which is dyed in mass during the winter period can cause reduced light transmission to a building especially on the northern side.

In order to preserve the high level of light transmission, as well as significantly reducing the infiltration of solar energy it is necessary to use the following:

– Selective solar control glass (dual function)

Facade glazing

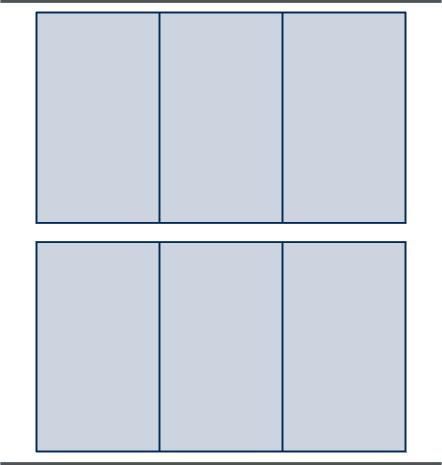

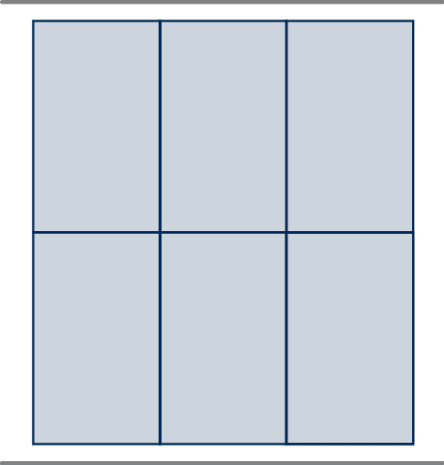

Press Glass produces double glazed glass units for all construction systems:

With almost unlimited design versatility, structural glazing has redefined modern architecture. The dream of architects and facade designers of creating a visual impression of a monolithic glass structure has finally come true, thanks to the use of either structural glazing or bolt fixing. Depending on the construction methods applied, there are four kinds of structural glazing:

ADVANTAGES

Structural glazing – Smooth glass surface of facades

In order to achieve the effect of a smooth surface in facades it is necessary to apply the appropriate construction system. This is known as structural glazing. This decision should be taken at the stage of designing a building.

By the term “ structural glazing” we mean the technology of attaching a glass structure to the building structure, where structural glazing silicon sealant serves as the binding agent.

Structural glazing can be supported, and then the dead weight of the panel is transferred by a suitable mechanical support; and is not supported, when the dead weight of the panel is transferred solely by an adhesive.

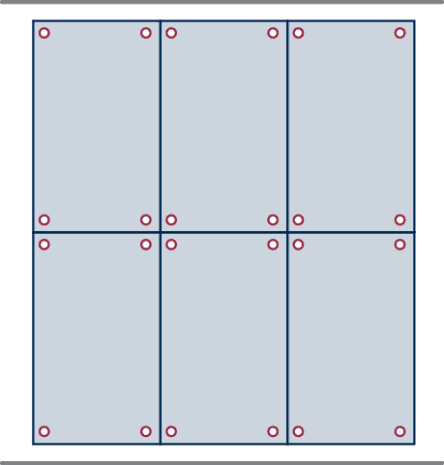

- two-sided systems – using a two-sided structural glazing technique, either the vertical or horizontal joints are adhered to the supporting structure;

- four-sided systems – when using a four-sided system, no mechanical retention is used for the facade panels;

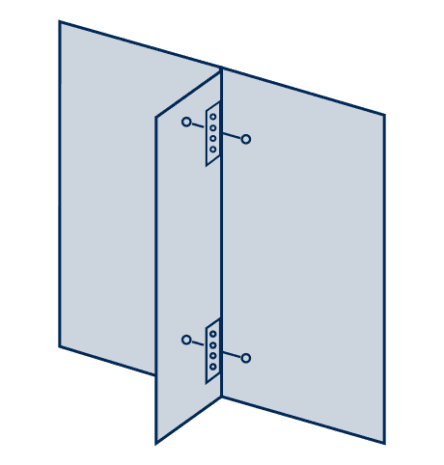

Bolt fixing – Easy mechanical fastening

Structural glazing can be supported, and then the dead weight of the panel is transferred by a suitable mechanical support; and is not supported, when the dead weight of the panel is transferred solely by an adhesive.

- bonded fixing systems – in this system the bolts are fixed directly onto the glass via a circular structural silicon seal which acts as a fixing point;

- fin glazing systems – the fin glazing technique employs glass panes which run from the frame of the building, perpendicular to the facade, which is then bonded to the fins using specific structural silicon sealants.

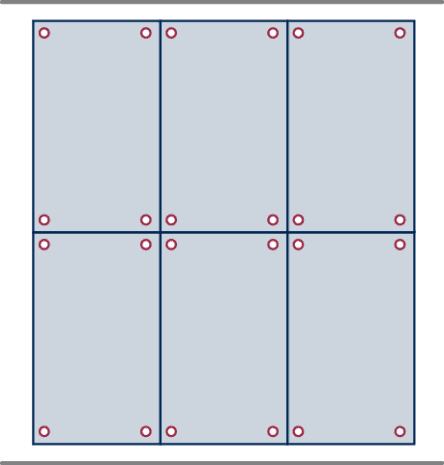

Bolt fixing is a system for securing glazing to a load-bearing structure by means of steel bolts going through the glass and mounted in specially designed holes. Bolt fixing allows designers to create perfectly smooth and transparent glass surfaces making up facades which are virtually invisible barriers between the interior and the exterior space of a building. It imposes no limitations as regards the height of the building and gives the architects almost unlimi-ted design versatility thanks to the direct fixing of glass panes to a load-bearing structure.

As with the structural glazing, bolt fixing can be used with a variety of glass types e.g. clear, low-emission, solar control – absorptive and reflective, as well as with a combination of glass types. Whatever glass type is used, however, it has to undergo heat treatment for greater resistance to thermal stresses.

Requirements

Sealants used in structural glazing have to meet the most stringent requirements for strength and durability. They have to be resistant to ultraviolet radiation and changing weather conditions. Final sealing of the assembled units is made with silicon sealants of similar characteristics to the structural sealants.

Designing glass facades is a task which requires expertise from architects and designers and experience on the part of the technical staff. Therefore, we must warn customers against commissioning haphazard people for mounting and fixing, as the results of this action become evident after a few years and the investor covers the costs.

Press Glass is an acknowledged contractor for fixing structural glazing with Dow Corning sealants.

We constantly modify our manufacturing processes and change habits to limit the negative effect on the environment.

In order to facilitate the changes, we have adopted ISO 14001, the worldwide management system for environmental protection.