Glazed units with warm edge

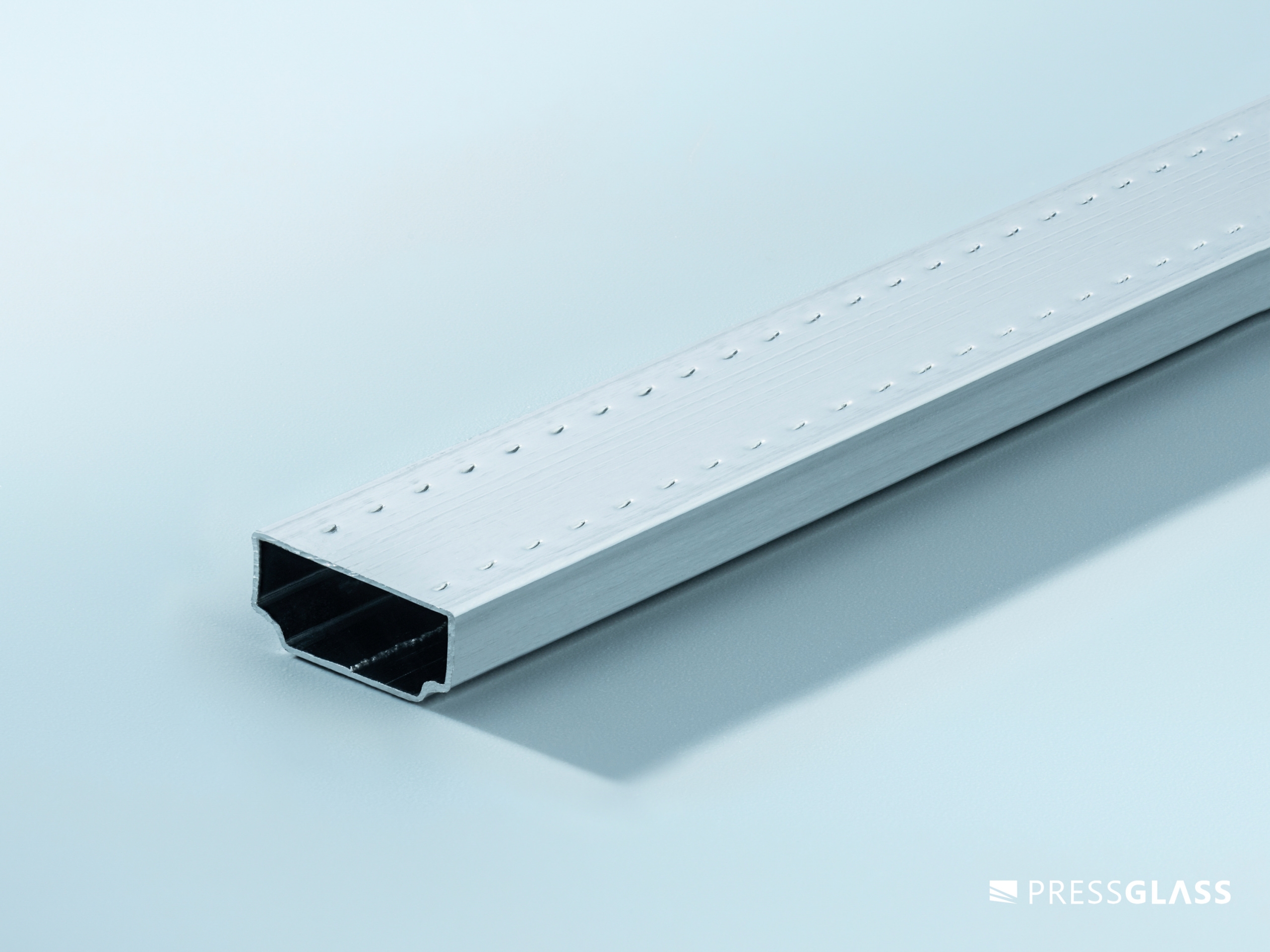

Until recently, aluminium spacer bars were generally used in double glazing.

However, with ever improving window frame and glazing heat conductivity coefficient values, aluminium bars were shown to be the weak point in glass unit construction.

Warm edge

Objectives

Aluminium has significantly greater heat conductivity than the remaining window components. The aluminium spacer bar around the edge of the pane is the last route of excessive heat penetration from the room to the exterior. This effect has been taken into account in the new approach to calculation of the coefficient Uw of the window and has been described with coefficient Psi (Ψ). The solution to this problem may be the application of a spacer bar – called warm edge*, executed from compound insulation material or fine steel.

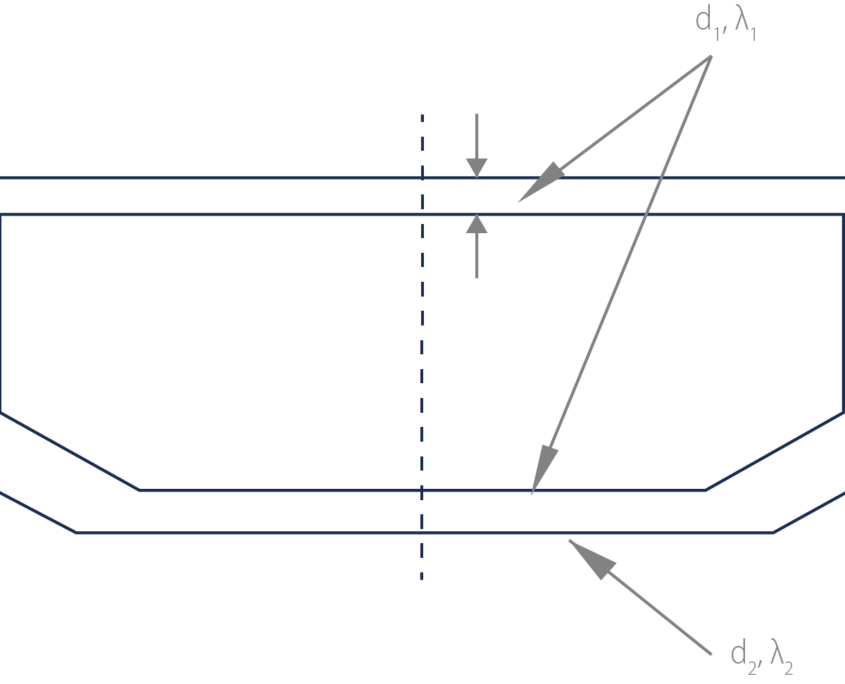

Warm edge criterion according to EN ISO 10077-1

To the time of establishing clear criteria enabling the definition of the warm edge concept, many spacer bars in glass units were sold on the market, which were indeed warmer than aluminium bars however had incomparably worse properties than correct solutions. According to this bars with improved design standard parameters are those, in which the spacer bar fulfils the following inequality:

Σ (diλi) ≤ 0,007 W/K

where:

di – thickness of partition material

λi – television of conductivity of material in W/mK

Example: 2(d1λ1) + (d2λ2) ≤ 0,007 W/K

The table below shows how particular types of bars fulfill the raised criterion:

| Types of bars | Value ∑ (di x λi)

EN ISO 10077-1 |

Qualification assessment

of spacer bar as “warm edge” |

| Aluminium | 0,1120 | negative |

| Stainless steel Chromatech |

0,0052 | positive |

| Chromatech Ultra | 0,0026 | positive |

| Termo TGI | 0,0020 | positive |

| Swisspacer Advance | 0,0019 | positive |

| Swisspacer Ultimate | 0,00002 | positive |

| Multitech G | 0,00002 | positive |

It should be emphasised that the actual effect of a thermal bridge on the edges of glass units mounted in windows depends on the type of spacer bar, heat insulation of the central part of the glass unit and the depth of the pane seating in profile and the coefficient of heat penetration Uf of profile.

Together with the increase in seating depth of the pane the proportion of heat loss of windows through the edge is reduced and minimises the possibility of the occurrence of water vapour. The table presented below compares the coefficient Psi of the most popular bent in corners warm edges* on the market with aluminium spacer bars.

| Ug | Construction of glazed units |

Window Frame |

Type of spacer bar | Psi factor |

| 1,1 | 4/16/4T Ar | PVC | Aluminium | 0,0653 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Aluminium | 0,0663 |

| 1,1 | 4/16/4T Ar | PVC | Stainless steel – Chromatech | 0,0511 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Stainless steel – Chromatech | 0,0501 |

| 1,1 | 4/16/4T Ar | PVC | Termo – TGI | 0,0401 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Termo – TGI | 0,0381 |

| 1,1 | 4/16/4T Ar | PVC | Chromatech Ultra | 0,0391 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Chromatech Ultra | 0,0371 |

| 1,1 | 4/16/4T Ar | PVC | Swisspacer Advance | 0,0391 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Swisspacer Advance | 0,0371 |

| 1,1 | 4/16/4T Ar | PVC | Swisspacer Ultimate | 0,0321 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Swisspacer Ultimate | 0,0301 |

| 1,1 | 4/16/4T Ar | PVC | Multitech G | 0,0311 |

| 0,7 | 4T/12/4/12/4T Ar | PVC | Multitech G | 0,0291 |

| 1,1 | 4/16/4T Ar | Wood | Aluminium | 0,0713 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Aluminium | 0,0763 |

| 1,1 | 4/16/4T Ar | Wood | Stainless steel – Chromatech | 0,0531 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Stainless steel – Chromatech | 0,0541 |

| 1,1 | 4/16/4T Ar | Wood | Termo – TGI | 0,0401 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Termo – TGI | 0,0391 |

| 1,1 | 4/16/4T Ar | Wood | Chromatech Ultra | 0,0391 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Chromatech Ultra | 0,0381 |

| 1,1 | 4/16/4T Ar | Wood | Swisspacer Advance | 0,0391 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Swisspacer Advance | 0,0371 |

| 1,1 | 4/16/4T Ar | Wood | Swisspacer Ultimate | 0,0311 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Swisspacer Ultimate | 0,0291 |

| 1,1 | 4/16/4T Ar | Wood | Multitech G | 0,0301 |

| 0,7 | 4T/12/4/12/4T Ar | Wood | Multitech G | 0,0281 |

| 1,1 | 4/16/4T Ar | Aluminium | Aluminium | 0,0802 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Aluminium | 0,1102 |

| 1,1 | 4/16/4T Ar | Aluminium | Stainless steel – Chromatech | 0,0681 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Stainless steel – Chromatech | 0,0661 |

| 1,1 | 4/16/4T Ar | Aluminium | Termo – TGI | 0,0491 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Termo – TGI | 0,0441 |

| 1,1 | 4/16/4T Ar | Aluminium | Chromatech Ultra | 0,0481 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Chromatech Ultra | 0,0431 |

| 1,1 | 4/16/4T Ar | Aluminium | Swisspacer Advance | 0,0471 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Swisspacer Advance | 0,0421 |

| 1,1 | 4/16/4T Ar | Aluminium | Swisspacer Ultimate | 0,0361 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Swisspacer Ultimate | 0,0311 |

| 1,1 | 4/16/4T Ar | Aluminium | Multitech G | 0,0351 |

| 0,7 | 4T/12/4/12/4T Ar | Aluminium | Multitech G | 0,0301 |

1 The data is given on the basis of the IFT Guideline WA-17/1

2 The data according to guidelines EN ISO 10077 – 1:2007

3 Data from the supplier aluminum spacer bar

DOWNLOAD PSI (Ψ) FACTOR DATASHEETS – WINDOWS

DOWNLOAD PSI (Ψ) FACTOR DATASHEETS – FACADES

From the table above it is shown that the application of plastic or stainless steel warm spacer bars reduces Psi coefficient to 35% in relation to panes with aluminium spacer bar. The effect of this is an increase of window temperature from the side of the room on the contact of frame with glass unit. With the effect that permissible relative air moisture, which in given conditions forms water vapour may due to the application of “warm edges” be higher by approx. 10-15% and shall not cause occurrence of water vapour condensation.

The permissible external minimal temperature is also reduced, at which water vapour condenses on pane surfaces. The table below presents an example of temperature breakdown on window surface from room side of various types of distance bar for Ug=1.1 4/16/4T Ar.

| Test conditions | Type of window frame profile | Type of spacer bar | Temperature at edges of internal panes in glass unit [°C] | Δt the edge and in the middle of glass unitinternal pane [°K] | Moisture dew point at edge of internal pane [%] | ||

| External temperature 0°C internal temperature +20°C | Wood | Plastic | 13,3 | 4,5 | 64,1 | ||

| Stainless steel | 12,4 | 5,2 | 62,8 | ||||

| Aluminium | 10,8 | 6,8 | 55,7 | ||||

| PCV | Plastic | 13,2 | 4,7 | 64,3 | |||

| Stainless steel | 12,5 | 5,3 | 62,3 | ||||

| Aluminium | 11,1 | 6,7 | 56,2 | ||||

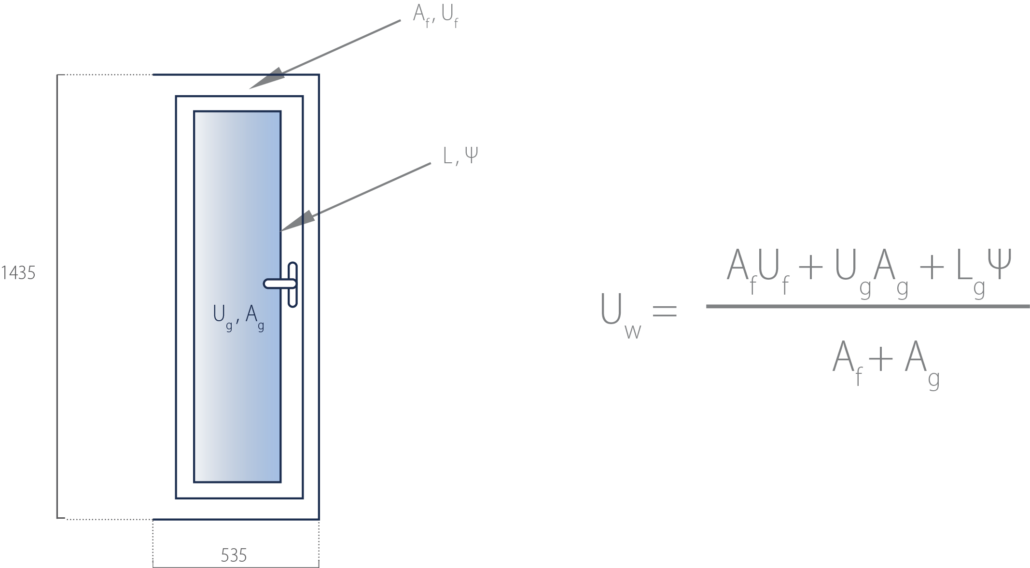

EXAMPLE OF CALCULATION OF Uw COEFFICIENT

Method of calculating coefficient of heat penetration of window Uw, in which the influence of the connection of the frame with the pane is taken into account is indicated in Standard EN ISO 10077 in the form of the following formula:

Uw – coefficient of heat penetration of window [W/m2K]

Af – surface of frame

Uf – coefficient of heat penetration [W/m2K]

Ag – glazed surface w [m2]

Ug – coefficient of heat penetration of pane [W/m2K]

Lg – circumference [m] (edge of glass)

Ψ – Linear heat penetration of window [W/mK]

In order to introduce the above formula we present a calculation example for a single window O32 of dimensions 535 x 1435 mm. The window is executed from the three-cell PCV profile strip of a complete width of frame and window of 125 mm.

For calculation the following assumptions are accepted:

Af = 0,43 m2

Uf = 1,2 W/m2K

Ag = 0,3377 m2

Ug = 1,1 W/m2K

Lg = 2,94 m

Ψa = 0,08 W/mK (aluminium)

Ψb = 0,051 W/mK (Chromatech)

Ψc = 0,044 W/mK (Termo TGI)

Ψd = 0,039 W/mK (Chromatech Ultra)

Ψe = 0,037 W/mK (Swisspacer Advance)

Ψf = 0,032 W/mK (Swisspacer Ultimate)

Ψg = 0,030 W/mK (Multitech G)

Window with aluminium spacer bar (a):

Uw,a = 1,46

Window with Chromatech spacer bar (c):

Uw,b = 1,35

Window with Termo TGI spacer bar (b):

Uw,c = 1,32

Window with Chromatech Ultra spacer bar (d):

Uw,d = 1,31

Window with Swisspacer Advance spacer bar (e):

Uw,e = 1,30

Window with Swisspacer Ultimate spacer bar (f):

Uw,f = 1,28

Window with Multitech G spacer bar (g):

Uw,g = 1,27

The results received indicate that the coefficient Uw of a window with a warm edge is improved correspondingly in relation to a window with an aluminium spacer bar of:

7,6% for Chromatech bar

10,0% for Termo TGI bar

10,3% for Chromatech Ultra bar

11,0 % for Swisspacer Advance bar

12,3 % for Swisspacer Ultimate bar

13,0 % for Multitech G bar

Range offered

Standard offer

| Type of spacer bar | Colour | Widths |

| Termo TGI | RAL

grey 7035, 7040; brown 8003, 8016; black 9005; white 9016; |

8, 10, 12, 14, 15, 16, 18, 20, 22, 24 |

| Stainless steel Chromatech | natural | 8, 10, 12, 14, 15, 16, 18, 20 |

| Chromatech Ultra | RAL

grey 7035, 7040; brown 8003, 8016; black 9004; white 9016; |

8, 10, 12, 14, 16 18, 20, 22, 24 |

| Swisspacer Advance | RAL light grey 7035; light brown 8003; black 9005; white 9016; |

10, 12, 14, 15, 16, 18, 20 |

| Swisspacer Ultimate | RAL light grey 7035; black 9005; |

10, 12, 14, 16, 18 |

| MULTITECH G | light grey; black; |

10, 12, 14, 16, 18 |

Offer avalaible for request with Sales Department

| Type of spacer bar | Colour | Widths |

| Stainless steel Chromatech | black 9005 | 8, 10, 12, 14, 15, 16, 18, 20 |

| Swisspacer Advance | RAL

light grey 7035; light brown 8003; black 9005; white 9016; |

8, 11, 22, 24, 27 |

|

RAL titanium (grey 9023); dark brown 8014; sulfuric 1016; yellow-green 6018; beige-brown 1011; pastel yellow 1034; grassy 6010; sapphire 5003; iridescent green 6026; brown-green 7013; beige 1001; ivory 1015; red-brown 8012; |

8, 10, 11, 12, 14, 15, 16, 18, 20, 22, 24, 27 | |

| Swisspacer Ultimate |

RAL light grey 7035; black 9005; |

8, 11, 15, 20, 22, 24, 27, 32, 36 |

|

RAL titanium (grey 9023); white 9016; sapphire 5003; light brown 8003; dark brown 8014; sulfuric 1016; yellow-green 6018; iridescent green 6026; brown-green 7013; beige 1001; beige-brown 1011; pastel yellow 1034; grassy 6010; ivory 1015; red-brown 8012; |

8, 10, 11, 12, 14, 15, 16, 18, 20, 22, 24, 27, 32, 36 | |

| MULTITECH G | light grey; black; | 8, 15, 20, 22, 24 |

| dark grey; white; | 8, 10, 12, 14, 15, 16, 18, 20, 22, 24 |

Download application and watch gallery of warm edges on your mobile

ADVANTAGES

Reduction of the linear heat leakage bridge on the edges of the glass unit

The properties of thermally insulated glass are also influenced by the linear heat conductivity on the edges. Up to now aluminium spacerbars have been commonly used, which are essential elements of glass units, but they have proved to be poor elements in making double glazed glass units. Aluminium is a much better carrier of heat than the remaining parts of the window construction, so the aluminium spacerbar is the final exit point for heat to move from the interior to the external area. The solution to this problem is to apply a spacerbar known as “ a warm edge”, which is made from highly insulating material or precious steel.

Limitation of condensation of the edges of the glass unit

The solution to this problem is to apply the spacerbar known as “the warm edge”, which is made of highly insulating material or precious steel. The application of the warm edge improves the thermal insulation along the edges, which in turn increases the temperature in this area and reduces the risk of temporary water vapour condensation.

Summary of advantages

Making the choice of warm edge, included in the product range, we are concentrating on:

Movie

Glazing of glass

We constantly modify our manufacturing processes and change habits to limit the negative effect on the environment.

In order to facilitate the changes, we have adopted ISO 14001, the worldwide management system for environmental protection.