PROTECTION AGAINST FIRE

The continuing tendency to use glass in internal and external applications ensures the pleasant appearance of buildings and removes the barrier between the building and the outside world. However, the glazed separators must in many cases meet the fire-fighting regulations relating to flame-retardation and the safe evacuation of the building users. Those requirements are very often met through the use of fire-resistant glass.

ENABLING EVACUATION IN CASE OF FIRE

In rooms where glass is used in the partitions, there is a particularly high risk of fire spreading rapidly due to the low resistance of this material to high temperatures. In such cases, there is therefore a risk that evacuation may not be possible. This risk is temporarily eliminated by the use of specialised fire-resistant glass. This type of fire-resistant glass prevents toxic gases from entering adjacent rooms, as well as rising temperatures. When exposed to fire, there is also a change in the structure of the glass layers, which are responsible for the stability of the work under fire load. These layers form a hard and opaque layer. This gives the building occupants the time they need to evacuate.

ELIMINATION OF PANIC DURING THE FIRE

Every day when we are in buildings, we are exposed to the possibility of a sudden fire. In such a situation, it is particularly important to be able to evacuate people. However, the use of glass raises the additional concern that the sight of fire spreading through glass separators may cause increased panic. This could seriously impede evacuation and cause additional casualties. PRESS GLASS offers specialised fire-resistant glass that, in the event of fire, changes the structure of the internal layers responsible for the stability of the work under fire load. These layers form a monolithic, hard and non-transparent layer that stops heat and toxic gases, eliminating the risk of increasing panic at the sight of fire.

PYROBELITE & PYROBEL

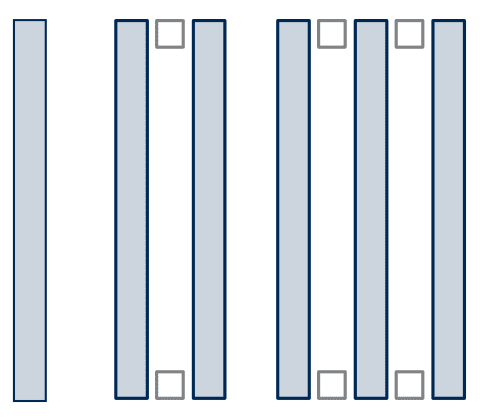

PRESS GLASS offers PYROBELITE & PYROBEL fire-resistant glass manufactured by the AGC. It is multi-layered glass, where the sheets of float glass are connected by means of intermediate layers made of gel, which expands under high temperature. During a fire, when the temperature rises to 120°C, the gel layers expand forming a hard, non-transparent layer, which temporarily prevents fire propagation.

Since we can combine the PYROBELITE and PYROBEL glass with laminated, coloured, reflexive and low-emission glass, we offer a wide range of glass panes combined with fire-resistant glass. This type of glass may perform different functions, such as: protection against burglary and noise, thermal and light insulation. As we have possibilities to process the fire-resistant glass, all our fire-resistant products are available with very short lead times. It must be remembered that the process of transforming fire-resistant glass into double-glazed units may not be commissioned to random manufacturers. That process requires specific manufacturing discipline due to the necessity of protecting the glass edges from coming into contact with the gel bonding of the panes by means of special aluminium foil. Direct contact with aggressive substances in the air or in water may lead to the fire-resistant glass layers losing their fire-resistant properties.

Similarly, special precautions must be applied during the fitting of double-glazed sheets in window frames in order to prevent the breaking of the protective layer securing the edges. The destruction of the protective layer may lead to the glass losing its properties and result in quicker flame propagation, as well as the inability to evacuate people from the building. In the event of the time spell between the glass manufacture and fitting in the window frame being very long, the inside surface of the fire-resistant glass must be protected from theUV radiation, as it is not protected by means of the PVB foil. Before orders are processed, clients ought to be notified of the general criteria defined by glass manufacturers, which must be followed during its application. The company which processes the glass sheets into double-glazed units is not responsible for the loss of the fire-resistant properties as a result of inappropriate fitting.

CLASSIFICATION

Our products meet three basic criteria specified in building standards:

- fire resistance (class E), creating a barrier to gases, fire and smoke but not lowering the temperature;

- fire resistance and radiation retention (class EW), creating a barrier to gases, fire and smoke and limiting the exchange of thermal radiation to 15 kW/m2;

- fire resistance and fire insulation (class EI), creating a barrier to gases, fire, smoke and temperature.

The average temperature on the surface unaffected by flames ought not to rise by more than 140 °C above the ambient temperature. To be precise, the temperature ought not to exceed 180 °C. In order to specify the time in which the glass meets the above requirements under the influence of fire, the glass classification symbol is supplemented with a numerical value indicating the time (in minutes), in which the fire-resistant glass meets the fireproof and the fire-insulation requirements. The PYROBELITE and PYROBEL glass types have been tested in many countries against the local standards in force. Both glass types were also subjected to fire tests in Instytut Techniki Budowlanej (the Building Research Institute) in Warsaw, as a result of which they have received a number of Polish technical approvals. However, it must be remembered that in accordance with the generally applicable regulations, certifications are not issued solely for fire-resistant glass.

The certifications relate to complex glass systems and not to their particular elements. The investor can not therefore demand a supplier to submit a document classifying a glass pane with respect to its fire-resistant properties. In order to obtain the certification, one must apply to the manufacturer or the supplier of system solutions. On account of the fact that fire-resistant glass may be built in internally or externally as monolithic or double-glazed glass, the Glaverbel and PRESS GLASS offer includes glass types, which are quite different with respect to their construction. On ac-count of the fact that the gel binding of the glass is characterised by high sensitivity to UV radiation, the fire-resistant glass used externally must be secured by means of the PVB foil on the side of the glass most exposed to UV radiation. It is assumed that in the case of the transparent external glass not having a safety layer in the form of the PVB foil, the fire-resistant glass for internal applications may be fitted within a minimum of 3.5 metres from that external glass.

TYPES OF PRODUCTS

TYPES OF PRODUCT

| Trade name | Type | Thickness [mm] |

Thickness tolerance [mm] |

Minimal dimension * [mm] |

Weight [kg/ m2] |

Rw (C,Ctr) [dB] |

LT [%] |

Safety class EN 12600 |

||

| PYROBELITE 7 |

EW30 | 7,9 | +/- 0,9 | 100 x 500 | 17 | 34

(-0,-3) |

88 | 3(B)3 | ||

| PYROBELITE 9 EG |

EW30 | 12,06 | +/- 1,0 | 100 x 500 | 28 | 37

(-1,-2) |

86 | 1(B)1 | ||

| PYROBELITE 10 |

EW30 | 11 | +/- 1,0 | 100 x 500 | 26 | 37

(-1,-3) |

87 | 2(B)2 | ||

| PYROBELITE 12 |

EI 20, EW 60 | 12,3 | +/- 1,0 | 100 x 500 | 27 | 36

(-1,-3) |

87 | 2(B)2 | ||

| PYROBEL 8 |

EI15, EW30 | 9,3 | +/- 1,0 | 100 x 500 | 20 | 34

(-1,-3) |

88 | – | ||

| PYROBEL 8 EG |

EI 15, EW 30 | 13,1 | +/- 1,3 | 100 x 500 | 28 | 36

(-1,-3) |

87 | 1(B)1 | ||

| PYROBEL 16 |

EI 30, EW 60 | 17,3 | +/- 1,0 | 100 x 500 | 40 | 39

(-1,-3) |

85 | 2(B)2 | ||

| PYROBEL 16 EG |

EI 30, EW 60 | 21,2 | +/- 1,5 | 100 x 500 | 48 | 39

(-1,-3) |

84 | 1(B)1 | ||

| PYROBEL 17 N |

EI 45 | 17,8 | +/- 1,6 | 100 x 500 | 40 | 39

(-0,-3) |

86 | 1(B)1 | ||

| PYROBEL 17 N EG |

EI 45 | 21,6 | +/- 1,8 | 100 x 500 | 48 | 40

(-1,-3) |

85 | 1(B)1 | ||

| PYROBEL 25 |

EI 60 | 26,6 | +/- 2,0 | 100 x 500 | 60 | 40

(-1,-3) |

82 | 1(B)1 | ||

| PYROBEL 25 EG |

EI 60 | 30,4 | +/- 2,0 | 100 x 500 | 68 | 43

(-1,-4) |

80 | 1(B)1 | ||

| PYROBEL 30 |

EI 90 | 30,0 | +/- 2,5 | 100 x 500 | 69 | 42

(-1,-4) |

81 | 1(B)1 | ||

| PYROBEL 30 EG |

EI 90 | 33,7 | +/- 2,8 | 100 x 500 | 77 | 43

(-1,-4) |

80 | 1(B)1 | ||

| PYROBEL 30 EG2 |

EI 90 | 37,5 | +/- 3,0 | 100 x 500 | 85 | 44

(-1,-4) |

80 | 1(B)1 | ||

| PYROBEL 54 |

EI 120 | 54 | +/- 3,0 | 100 x 500 | 124 | 49

(-1,-4) |

75 | 1(B)1 | ||

| PYROBEL 54 EG |

EI 120 | 57,8 | +/- 3,0 | 100 x 500 | 132 | 49

(0,-3) |

74 | 1(B)1 | ||

| PYROBEL 19H |

EI 30 | 19,1 | +/- 1,5 | – | 43 | 38

(-1,-3) |

85 | 1(B)1 | ||

| PYROBEL 23H |

EI 45 | 23,7 | +/- 1,8 | – | 54 | 39

(-0,-3) |

83 | 1(B)1 | ||

| PYROBEL 28H |

EI 60 | 28,4 | +/- 2,0 | – | 63 | 41

(-0,-3) |

78 | 1(B)1 | ||

| PYROBEL 33H |

REI 60 | 33,2 | +/- 2,5 | – | 77 | 44

(-1,-4) |

80 | 1(B)1 | ||

| *Relates to double-glazed glass sheets

**Dimensions tolerance [mm] +/- 2 mm EG – External glazing H – Horizontal glazing |

||||||||||

The information provided below contains additional remarks which enable interested parties to find out more details associated with purchasing fire resistant glass units. Due to the requirements with respect to fire resistant glass units, the production and ordering must involve additional procedures which is not the case with other products. The standard market offer of PRESS GLASS comprises of double glazed fire resistant glass, designed for use in interior or outdoor partition walls. Single glazed fire resistant glass units for outdoor partition walls are available in the non-standard market offer.

The maximum dimensions used are however limited by technical approvals that define the maximum homologated dimensions of glass panes.

While ordering glass units it is essential to check the maximum dimensions allowed in the approval each time.

STANDARD OFFER OF FIRE RESISTANT GLAZED UNITS:

|

Product |

Type* |

| VSG 44.2 Thermofloat/ 8 /Pyrobelite 7 | EW 30 |

| VSG 44.2 Thermofloat/ 8 / Pyrobel 16 | EI 30

EW 60 |

| VSG 44.2 Thermofloat/ 8 / Pyrobel 17N | EI 45 |

| VSG 44.2 Thermofloat/ 8 / Pyrobel 25 | EI 60 |

| VSG 44.2 Thermofloat/ 8 / Pyrobel 30 | EI 90 |

*The classification of resistance has been presented on the basis of tests carried out for the complete system. In the case of using another system or elements of a different system to that shown in the approvals, the classification of fire-resistance may not be achieved.

In the case of ordering double glazed reflexive solar control glass and glass which is edged in mass, it is necessary to receive advice as to the possibility of application due to the limitations associated with the heating of fire resistant glass. This is associated with the phenomenon of heat energy absorption in the glass mass, which in effect can cause degradation of the gel, which is a component of fire resistant glass, under the impact of excessive temperatures.

Construction firms that order double glazed glass often avail of forms which they prepare themselves. However, in the case of ordering fire resistant glass units, orders should be made using forms prepared by PRESS GLASS. It is necessary to provide the name of the glazing system which will involve the use of glass units and the valid number of the technical approval. Moreover, the form containing the order should include the information provided in the table below:

| No. | Glass unit external + position of coating | Type of spacebar + width (mm) | Inside Glass unit | Width (mm) | Height (mm) | Quantity | Glazing system (name and number of technical approval) |

PRESS GLASS marks fire resistant glass units known as Pyrobel and Pyrobelite with a permanent stamp which includes the following:

- marking the type of fire resistant glass: Pyrobel or Pyrobelite

- marking of classification as regards resistance

- identification symbol of the producer of the glass units: PRESS GLASS

- month and year of production with regard to the glass unit

Additionally, glass units for inside use are marked with an appropriate label aimed at clearly specifying the designed glazing application. Assessment of defects in fire resistance glass units is carried out on the basis of the norms known as PN-EN ISO 12543 entitled “Laminated glass and safe laminated glass”. Realization of standard orders does not exceed 14 days and the period of guarantee commences on the day of final production of the glass units.

Usage

PYROBELITE & PYROBEL can be used wherever construction regulations require it and where natural lighting and transparency of the partition are necessary.

Such places include, among others:

- hospitals and laboratories;

- schools and offices;

- hotels and restaurants;

- theatres and museums;

- shopping centres and metro stations;

- banks, etc.