PREMIUM EDGE

PREMIUM EDGE is an ecofriendly solution that tightly connects the whole perimeter of a glass unit, thereby protecting the user against loss of heat from the inside and against noise from the outside.

Structure

PREMIUM EDGE was developed together with Edgetech. It uses the triple insulation method with the Super Spacer spacer, strict quality control, the best insulating materials, as well as automated Lisec production lines for installing the spacer.

Advantages

Durability

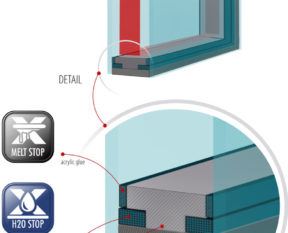

The triple insulation method is the key to the enhanced durability. The PREMIUM EDGE manufacturing technology provides primary insulation in the form of acrylic glue, as well as main and external insulations.

The acrylic glue is applied first, thereby fixing the spacer to the glass panes. As a result, the spacer does not move during the manufacture, and the main and secondary insulations do not penetrate to the inside of the glass unit, improving the aesthetics of the insulation.

The acrylic glue is applied first, thereby fixing the spacer to the glass panes. As a result, the spacer does not move during the manufacture, and the main and secondary insulations do not penetrate to the inside of the glass unit, improving the aesthetics of the insulation.

The main insulation and the leading Super Spacer T-Spacer Premium Plus spacer comprise the most important protection against damp permeating into the glass unit inside and against gas leakage.

These are applied automatically and continuously on the sides and in the corners and tightly connect the whole perimeter of a glass unit.

The external insulation stabilizes and reinforces the connection, and protects it against the direct exposure to weather conditions and mechanical factors.

The spacer is made of silicone foam which offers perfect flexibility in the temperature range of -40 to +120 °C. Consequently, the insulation is stable in all weather conditions, whether the glass unit serves as a part of a window or a facade.

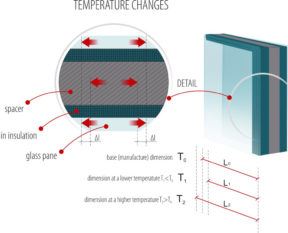

Due to temperature variations, materials comprising a glass unit change their dimensions.

The change can be described with the coefficient of linear expansion, and is different for each type of material. As a result, excessive expansion or compression of insulating materials may occur on the edge of a glass unit, where glass and spacer are connected. With time this may lead to the reduced adhesiveness of insulating materials for the glass and spacer, causing reduced tightness of a glass unit.

In the case of glass units with spacers made of rigid materials this process has greater influence on the edge durability. Then a difference (∆l) in the change of spacer and glass pane dimensions can be observed.

On the other hand, the Super Spacer spacer adapts its shape to the changes in the glass panes’ dimensions – as a result ∆I=0.

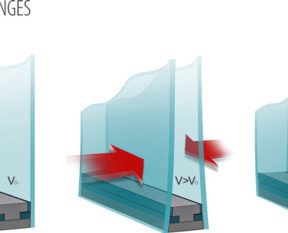

The spacer properties make it possible to safely transfer lateral forces that expand and compress glass panes due to changes in temperature and pressure.

Edge aesthetics

In PREMIUM EDGE, Press-Glas uses the automatic method of fixing the spacer to a glass pane, which makes it possible to install it perfectly straight and parallel.The Super Spacer spacer is resistant to changes in surface colour and to degradation caused by UV radiation; this has been successfully tested according to the EN 1279-6 standard.

Protection against cold and noise

PREMIUM EDGE is the best solution utilizing a spacer in terms of heat- and sound-insulation. The use of insulating layers of a suitable consistence and thickness, and the Super Spacer spacer are crucial. The spacer is made of porous silicone foam having a structure similar to the materials used to sound- and heatproof our houses. The molecular sieve for drying the air within the glass unit is included in the foam. Thus, the rattling effect, which is produced as a result of sieve vibration in a spacer, is absent, in contrast to spacers filled with the granular sieve.

Using glass units with PREMIUM EDGE makes it possible to improve window soundproofing by even 2 dB.

Comparative research by IFT Rosenheim has shown that the edge of a reference window with the Super Spacer spacer has the lowest Psi out of all the solutions tested to date. It allows us to reduce the Uw coefficient by even 0.2 W/m2K in comparison to solutions with an aluminium spacer.

Thanks to that, the possibility of steam precipitation and fungus on the connecting edge between the window profile and glass pane is reduced even more.

| Psi for common window types, based on * | ||||

| Glass unit structure | Frame type | Super Spacer | Thermo-TGI | |

| Ug=1,1 | 4/16/4T Ar | Wooden | 0,031 | 0,044 |

| Ug=0,7 | 4T/12/4/12/4T Ar | Wooden | 0,029 | 0,043 |

| Ug=1,1 | 4/16/4T Ar | PVC | 0,033 | 0,044 |

| Ug=0,7 | 4T/12/4/12/4T Ar | PVC | 0,031 | 0,041 |

| Ug=1,1 | 4/16/4T Ar | Aluminium | 0,037 | 0,056 |

| Ug=0,7 | 4T/12/4/12/4T Ar | Aluminium | 0,031 | 0,051 |

*lft-Guideline WA-08

Application

PREMIUM EDGE can be used with any type of basic glass pane, and meets all the qualification requirements designed for window glass panes and facade glazing. Internal mounting installation in glass units with PREMIUM EDGE is prohibited, as Press-Glas wants to ensure that the best acoustic and thermal parameters of its products are maintained.

Offer

| Available widths [mm] | 12,16 |

| Available colours | Black, Gray |